|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

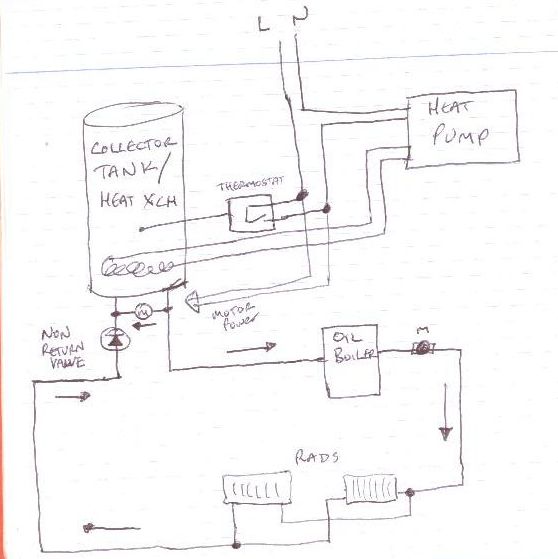

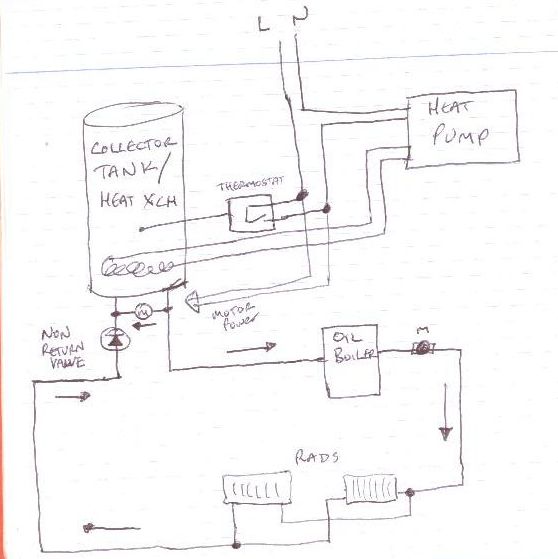

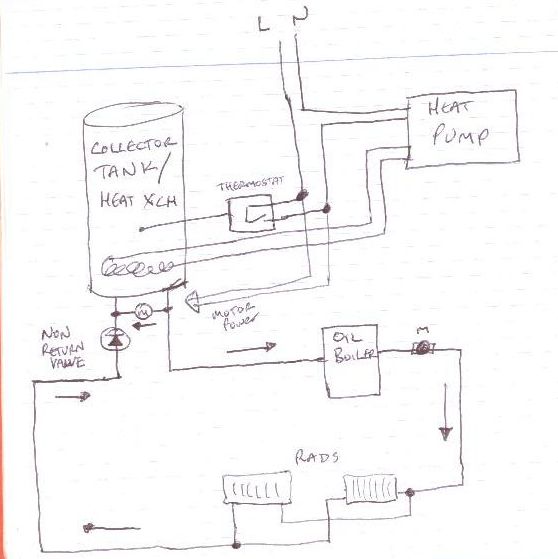

Schematic diagram of project

|

|

|

Following on from my successes with the pool heater project I decided there were more oportunities for using heat pumps to save energy.

This project is designed to augment rather than replace my oil fired boiler central heating system. Maybe at a later date the oportunity will arise to replace the boiler but for the moment I'm just looking at reducing my consumption of fuel oil. The idea is as follows:Heat pumps have a limit to the temperature that they can heat to, hence heat pumps are generally used with underfloor heating systems where the temperature is lower. They can also be used with oversized radiators or low temperature radiators but, as none of these is an option in my case, it has to fit in with what I have. My idea is to pre-heat the water on the return flow to the boiler; this is the point where the water is coolest as the heat has been lost from the radiators. Pre-heating the water should mean that the boiler has to work less to add the extra heat and (as it's a cast iron boiler) any residual heat will be transferred slower to the water passing through the boiler. The boiler should run much less than it currently does and should save oil. The other possibility is to harvest heat and store it in a collector tank during the day for release overnight. This is still a future project as I currently only have a 100 litre tank but as tanks become available in the future I will be able to extend the system. The tank I used is a horizontally mounted 100L hot water cylinder with a conventional immersion heater element. It is a tank I was asked to change by one of my customers due to it tripping out due to overheating. The problem was calcium build up on the heating element but rather than change the element they decided to change the whole heater - lucky me! The challenge was how to convert it from an electric heater to a tank with a refrigerant heating coil inside. It turned out to be relatively straightforward. The heating element is a wire coil inside a metal tube. This is actually soldered onto the mounting plate to provide a seal. There is also a hollow tube for the thermostat to slot into and a bolt to hold a sacrificial anode. Unsoldering the heater element and enlarging the holes slightly to enable the refrigerant pipes to pass through was not very challenging! I then built yet another MKII heat exchanger coil (see my Pool Heater Project for details), mounted the whole lot on the tank mounting plate and eased it all into the inside of the tank. Job done! My first try was with an unmodified aircon unit permanently switched to heat and without a circulating pump for the collector tank. This didn't work too well as the heat wasn't transferred quickly enough from the heat exchanger so the compressor overheated and shut down. This was the reason for the addition of the circulating pump that is in the schematic. The pump is intentionally installed to pull water from the outlet side of the tank and re-introduce it into the inlet side; if it was the other way around it would have the effect of bypassing the tank. The non return valve is to stop water being pumped backwards through the heating system. To enable better control of the heat pump I added a TXV to replace the capillary; I still have some fine tuning to do but initial tests are promising. The temperature where I live is still 30 degrees + so until it cools down I won't be able to perform many tests. From the short test I have performed, running the heatpump does heat the water in the collector tank quite quickly so I'm hopeful of some good results. The aircon unit I'm using is a Mitsubish Heavy Industries unit. I have no idea of it's age but it runs well. The compressor is a Mitsubishi RM5526 GNE4 unit; 2.14Kw in and around 6.1Kw heating capacity. It was originally charged with R22 but I've removed the gas and replaced it with RS44. It cost me 50 euros. |